Decoding Fastener Screw Threads: A Comprehensive Guide to Metric, American, and British Varieties

Fasteners serve as indispensable components in diverse mechanical and structural applications, acting as the linchpin that binds objects together. Within this intricate ecosystem, screw threads play a pivotal role, with Metric, American, and British threads emerging as three prominent variants. In this exploration, we unravel the unique characteristics, differences, and requirements of these essential components in the realm of fasteners.

Metric Screw Threads

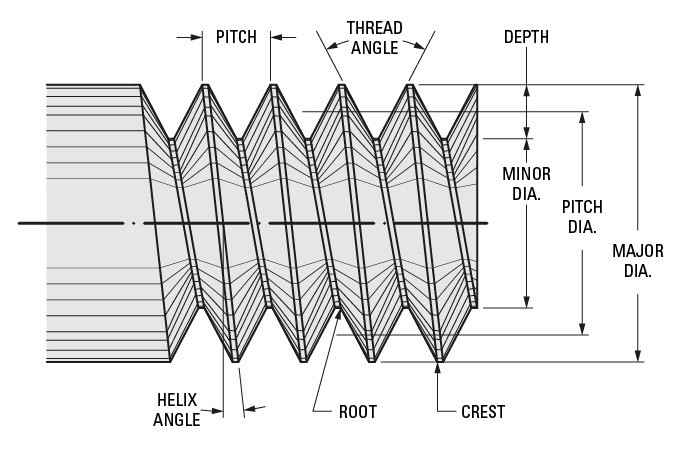

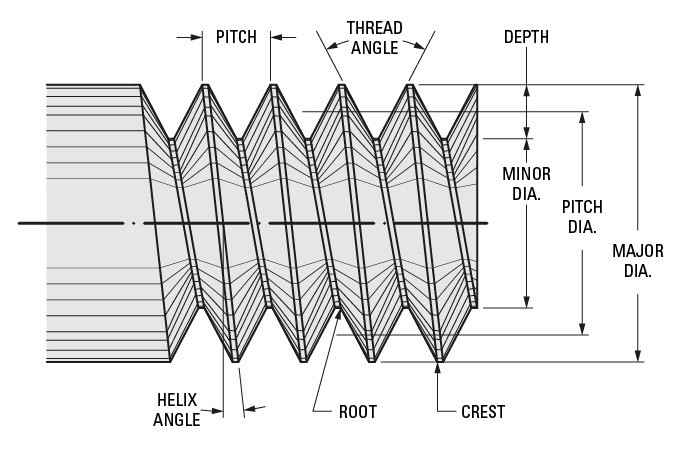

Metric screw threads, rooted in the International System of Units (SI), are widely employed in Europe and Asia. Designated by thread pitch—the distance between each thread crest along the screw's axis—they adopt a 60-degree thread angle and a symmetrical V-shape thread form. The distinguishing factor lies in the measurement system: Metric threads are quantified in millimeters, setting them apart from their American and British counterparts.

American Screw Threads

Prevalent in the United States, Canada, and Unified Thread Standard (UTS)-adhering countries, American screw threads offer versatility in coarse and fine types. Featuring a 60-degree thread angle and a flattened V-shape thread form, they are measured in threads per inch (TPI) for pitch and inches for diameter. The Unified Coarse (UNC), Unified Fine (UNF), and Unified Extra Fine (UNEF) series further classify American threads.

British Screw Threads

Found in the United Kingdom, Australia, and New Zealand, British screw threads categorize into Whitworth and British Standard Whitworth (BSW). With a 55-degree thread angle for Whitworth threads and a 60-degree angle for BSW threads, both exhibit a rounded V-shape thread form. Similar to American threads, British threads are measured in inches, with pitch in TPI and diameter in fractions of an inch. Common thread types encompass BSW (British Standard Whitworth), BSF (British Standard Fine), and BA (British Association).

Requirements of Screw Threads

Meeting specific requirements is imperative for screw threads to align with diverse applications. Key criteria include:

In the choice of fastener threads, the nuances and requirements of Metric, American, and British screw threads stand as significant considerations. Beyond mere measurement system variations, the thread angle, and thread form play pivotal roles. The selection of the appropriate screw thread, guided by application requirements, ensures a seamless fit, engagement, and torque transmission—a critical aspect in the realm of fasteners.

Metric Screw Threads

Metric screw threads, rooted in the International System of Units (SI), are widely employed in Europe and Asia. Designated by thread pitch—the distance between each thread crest along the screw's axis—they adopt a 60-degree thread angle and a symmetrical V-shape thread form. The distinguishing factor lies in the measurement system: Metric threads are quantified in millimeters, setting them apart from their American and British counterparts.

American Screw Threads

Prevalent in the United States, Canada, and Unified Thread Standard (UTS)-adhering countries, American screw threads offer versatility in coarse and fine types. Featuring a 60-degree thread angle and a flattened V-shape thread form, they are measured in threads per inch (TPI) for pitch and inches for diameter. The Unified Coarse (UNC), Unified Fine (UNF), and Unified Extra Fine (UNEF) series further classify American threads.

British Screw Threads

Found in the United Kingdom, Australia, and New Zealand, British screw threads categorize into Whitworth and British Standard Whitworth (BSW). With a 55-degree thread angle for Whitworth threads and a 60-degree angle for BSW threads, both exhibit a rounded V-shape thread form. Similar to American threads, British threads are measured in inches, with pitch in TPI and diameter in fractions of an inch. Common thread types encompass BSW (British Standard Whitworth), BSF (British Standard Fine), and BA (British Association).

Requirements of Screw Threads

Meeting specific requirements is imperative for screw threads to align with diverse applications. Key criteria include:

- Thread Pitch: Accurate specification ensures proper mating of the threads.

- Thread Angle: Uniformity in thread angle guarantees effective torque transmission, preventing thread stripping.

- Thread Form: Accurate specification ensures a proper fit and engagement of the threads.

- Tolerance: Defined tolerance levels prevent thread damage and ensure precise mating.

- Surface Finish: Accurate specification of surface finish guarantees effective sealing and prevents leakage.

In the choice of fastener threads, the nuances and requirements of Metric, American, and British screw threads stand as significant considerations. Beyond mere measurement system variations, the thread angle, and thread form play pivotal roles. The selection of the appropriate screw thread, guided by application requirements, ensures a seamless fit, engagement, and torque transmission—a critical aspect in the realm of fasteners.