Unlocking the Potential of Flange Screws: Types, Applications, and Advantages

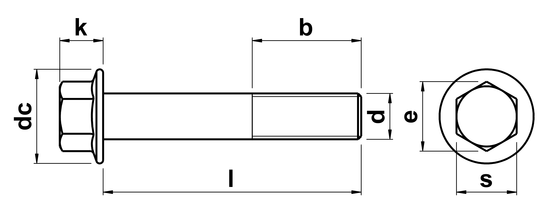

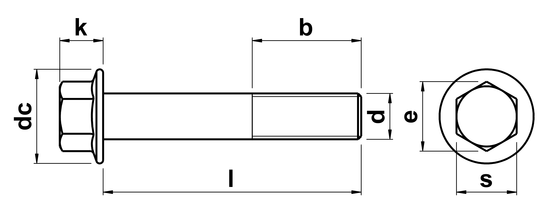

Flange screws, integral fasteners featuring a built-in flange, have emerged as indispensable components in the industrial and construction sectors, ensuring secure and stable fastening. In this comprehensive exploration, we delve into the intricacies of flange screws, covering their diverse types, versatile applications, and the manifold benefits they bring to various industries.

The Common Flange Screws Types

The versatility of flange screws is evident in their availability across various sizes and materials, adapting to diverse applications. The following represent some of the prominent types:

Major Benefits of Flange Screws

The advantages offered by flange screws position them as preferred fasteners in various applications:

Applications of Flange Screws

Flange screws, with their secure fastening capabilities, find extensive utility across various industries. Key applications include:

As professionals navigate the intricate landscape of fasteners, the comprehensive advantages of flange screws position them as an essential choice, adaptable to various applications and environments, solidifying their status as a cornerstone in the realm of fastening technology.

The Common Flange Screws Types

The versatility of flange screws is evident in their availability across various sizes and materials, adapting to diverse applications. The following represent some of the prominent types:

- Hex Flange Screws: Boasting a hexagonal head tailored for wrench or socket use, these screws find their niche in automotive and industrial realms.

- Torx Flange Screws: Distinguished by a six-pointed star-shaped head, these screws offer enhanced grip, particularly beneficial in high-torque scenarios prevalent in aerospace and electronics industries.

- Phillips Flange Screws: Characterized by a cross-shaped head compatible with a Phillips screwdriver, these screws play a pivotal role in woodworking and construction applications.

- Socket Head Flange Screws: Featuring a cylindrical head with a socket designed for an Allen wrench, these screws are integral to the assembly of machinery and equipment.

Major Benefits of Flange Screws

The advantages offered by flange screws position them as preferred fasteners in various applications:

- Increased Bearing Surface Area: The intrinsic flange design provides a substantial bearing surface, effectively distributing loads evenly and minimizing the risk of surface damage.

- Improved Grip: Going beyond conventional screws, flange screws offer an enhanced grip, thanks to the incorporated flange acting as a washer, mitigating the risk of loosening over time.

- Reduced Need for Additional Washers: Streamlining the fastening process, flange screws eliminate the necessity for extra washers, thereby reducing both cost and complexity.

- High Strength and Durability: Engineered for robust performance, flange screws exhibit high strength and durability, making them ideal for deployment in demanding and strenuous applications.

- Reduced Risk of Corrosion: Often forged from corrosion-resistant materials, such as stainless steel, flange screws significantly reduce the risk of corrosion, contributing to an extended lifespan of the fastener.

Applications of Flange Screws

Flange screws, with their secure fastening capabilities, find extensive utility across various industries. Key applications include:

- Automotive Industry: Beyond conventional use, flange screws secure components such as engine parts, body panels, and suspension systems, ensuring reliability in demanding automotive applications.

- Construction Industry: The versatility of flange screws shines through in construction tasks, ranging from attaching metal roofing and siding to securing wooden beams and fastening drywall to studs.

- Electronics Industry: Recognized for their reliability, flange screws play a crucial role in the electronics industry, securing components to circuit boards and enhancing the structural integrity of electronic devices.

- Aerospace Industry: Acknowledged for their high strength and durability, flange screws are indispensable in aerospace applications, playing a vital role in attaching engines to aircraft and securing critical structural components.

As professionals navigate the intricate landscape of fasteners, the comprehensive advantages of flange screws position them as an essential choice, adaptable to various applications and environments, solidifying their status as a cornerstone in the realm of fastening technology.