Unveiling the Sealing Excellence of Metal Spiral Wound Gaskets

In terms of mechanical seals, the metal spiral wound gasket emerges as a formidable solution designed to securely seal two flanges in environments characterized by high temperatures, pressures, and corrosive fluids. This innovative sealing technology of this gasket relies on a meticulous combination of key elements, each contributing to its robust performance.

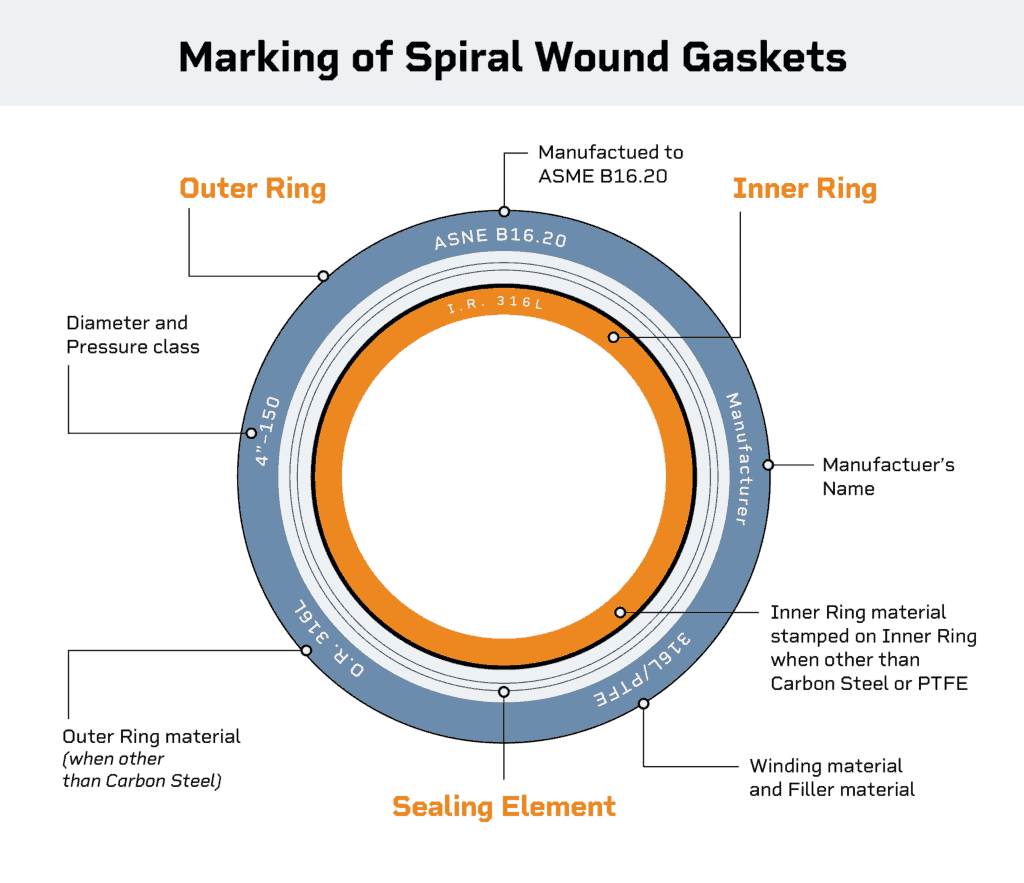

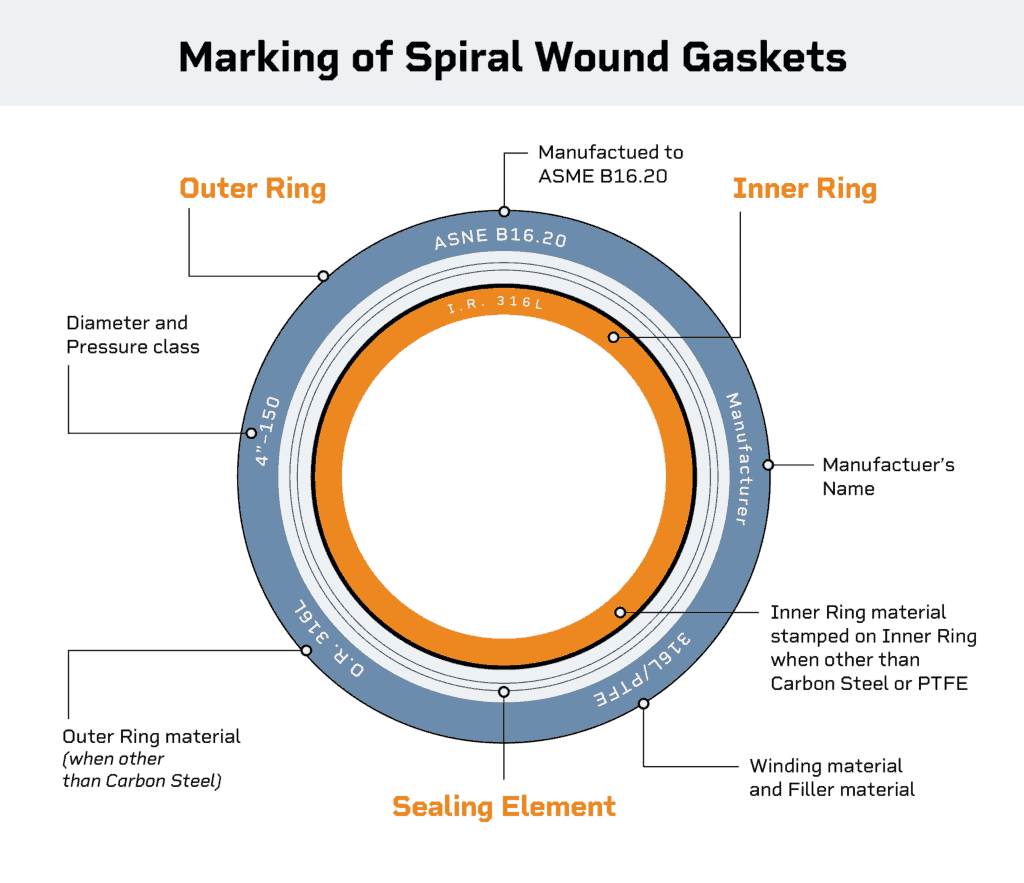

1. Structural Components: Inner and Outer Rings

At the core of the metal spiral wound gasket's design are the inner and outer rings, serving distinct yet crucial functions. The inner ring, crafted from a softer material than the metal winding, acts as a compression stop. Its role is to prevent any buckling or movement of the metal windings during compression. On the other hand, the outer ring serves as a centering device, aligning the gasket precisely with the flange faces to ensure uniform compression.

2. Filler Material: Graphite, PTFE, or a Blend

The filler material within the gasket is a critical component responsible for imparting sealing characteristics. Typically made of graphite, PTFE, or a combination of both, the filler material plays a pivotal role in creating an effective seal. Graphite is favored for its excellent thermal conductivity, chemical resistance, and compressibility, while PTFE's low friction coefficient and chemical resistance make it a preferred choice.

3. Metal Winding: Structural Strength for Endurance

The metal winding, forming a spiral pattern around the filler material, provides the structural backbone of the gasket. Typically crafted from stainless steel, and in some cases, materials like Inconel, Monel, or Hastelloy based on application requirements, the metal winding ensures the gasket's ability to withstand extreme pressures and temperatures.

Sealing Principle in Action

When compressed between two flanges, the inner ring acts as a compression stop, preventing any undesirable movement of the metal winding. Simultaneously, the outer ring guarantees proper alignment with flange faces, ensuring uniform compression. As the gasket undergoes compression, the filler material is forced into irregularities on the flange faces, creating a robust seal. The metal winding's structural strength enables the gasket to endure the forces generated by compression, ensuring its integrity over time.

Effectiveness in Extreme Conditions

The amalgamation of the inner and outer rings, filler material, and metal winding makes the metal spiral wound gasket a highly effective solution for extreme conditions. The inner ring maintains structural integrity during compression, the outer ring ensures uniform compression, the filler material provides sealing characteristics, and the metal winding imparts structural strength.

In conclusion, the metal spiral wound gasket's sealing principle relies on the harmonious interaction of its integral elements. Properly designed and installed, this gasket stands as a reliable sealing solution for applications demanding resilience in high-temperature, high-pressure, and corrosive environments. Its multifaceted design ensures effectiveness, making it an indispensable component in challenging industrial settings.

1. Structural Components: Inner and Outer Rings

At the core of the metal spiral wound gasket's design are the inner and outer rings, serving distinct yet crucial functions. The inner ring, crafted from a softer material than the metal winding, acts as a compression stop. Its role is to prevent any buckling or movement of the metal windings during compression. On the other hand, the outer ring serves as a centering device, aligning the gasket precisely with the flange faces to ensure uniform compression.

2. Filler Material: Graphite, PTFE, or a Blend

The filler material within the gasket is a critical component responsible for imparting sealing characteristics. Typically made of graphite, PTFE, or a combination of both, the filler material plays a pivotal role in creating an effective seal. Graphite is favored for its excellent thermal conductivity, chemical resistance, and compressibility, while PTFE's low friction coefficient and chemical resistance make it a preferred choice.

3. Metal Winding: Structural Strength for Endurance

The metal winding, forming a spiral pattern around the filler material, provides the structural backbone of the gasket. Typically crafted from stainless steel, and in some cases, materials like Inconel, Monel, or Hastelloy based on application requirements, the metal winding ensures the gasket's ability to withstand extreme pressures and temperatures.

Sealing Principle in Action

When compressed between two flanges, the inner ring acts as a compression stop, preventing any undesirable movement of the metal winding. Simultaneously, the outer ring guarantees proper alignment with flange faces, ensuring uniform compression. As the gasket undergoes compression, the filler material is forced into irregularities on the flange faces, creating a robust seal. The metal winding's structural strength enables the gasket to endure the forces generated by compression, ensuring its integrity over time.

Effectiveness in Extreme Conditions

The amalgamation of the inner and outer rings, filler material, and metal winding makes the metal spiral wound gasket a highly effective solution for extreme conditions. The inner ring maintains structural integrity during compression, the outer ring ensures uniform compression, the filler material provides sealing characteristics, and the metal winding imparts structural strength.

In conclusion, the metal spiral wound gasket's sealing principle relies on the harmonious interaction of its integral elements. Properly designed and installed, this gasket stands as a reliable sealing solution for applications demanding resilience in high-temperature, high-pressure, and corrosive environments. Its multifaceted design ensures effectiveness, making it an indispensable component in challenging industrial settings.